Enter your keyword

MARKLON Poly Carbonate Sheet (SOLID SHEET)

MARKLON Poly Carbonate Sheet (SOLID SHEET)

Categories: All, ROOF SYSTEM

Tags: MARKLON

Stock:

In Stock

MARKLON Poly Carbonate Sheet (SOLID SHEET)

Marklon Polyglass Polycarbonate Solid Sheet: The Ultimate UV-Resistant Solution

Marklon Polyglass Polycarbonate Solid Sheet features a protective layer of high-density UV reflector, offering exceptional resistance to the damaging effects of UV light, thus minimizing long-term yellowing and hazing.

Features:

-

UV Resistance: The high-density UV reflector layer provides outstanding protection against UV light, ensuring long-lasting clarity and appearance.

-

Customizable: Available in a wide variety of standard colors, patterns, and dimensions, with the option for tailor-made or custom finishing to meet specific project requirements.

-

10-Year Limited Warranty: Marklon Polyglass® Polycarbonate Solid Sheet is backed by a 10-year limited warranty against extreme color deterioration and sheet cracking under normal weather conditions.

Benefits:

-

Durability: With exceptional UV resistance, these sheets maintain their clarity and appearance for an extended period.

-

Customization: The ability to customize colors, patterns, and dimensions allows for seamless integration into any project.

-

Warranty: The 10-year limited warranty provides peace of mind regarding the longevity and quality of the product.

Applications:

-

Greenhouses

-

Skylights

-

Canopies

-

Safety and security glazing

-

Architectural glazing

In summary, Marklon Polyglass® Polycarbonate Solid Sheet offers unparalleled UV resistance, customization options, and a comprehensive warranty, making it the ideal choice for a wide range of applications requiring durability and aesthetic appeal.

PC Solid Sheet

Superior quality resin from German & Japan

Color & Pattern

-

PLANE SERIES

-

LINE SERIES

-

GLASS SERIES

-

NU SERIES

-

DIAMOND SERIES

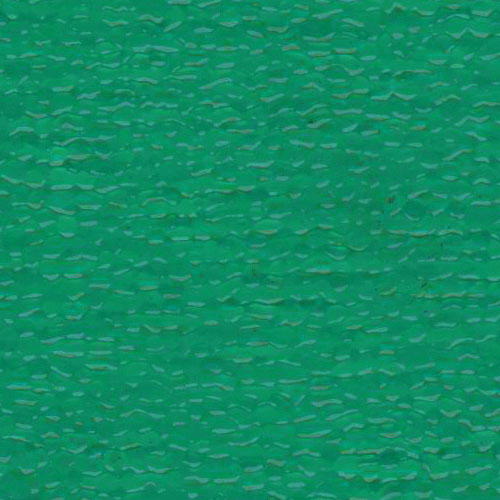

PLANE SERIES – COLOR

MK91 BROWN

MK91 BROWN MK92 BLUE

MK92 BLUE MK93 GREEN

MK93 GREEN

MK95 CLEAR

MK95 CLEAR  MK98 WHITE

MK98 WHITE

Thickness (MM)

1.0, 2.0, 3.0, 4.0, 4.5, 5.0, 6.0, 7.0, 8.0, 10.0

Lenght (MM)

Up to 30500 (100′) or cut to size

Width (MM)

1212

-

Non-standard product (width, length, thickness, colour) are available subject to a minimum order quantity

-

Thickness tolerance : subject to thickness tolerance

-

Colour only for reference, order based on sealed sample

Product Characteristics

General

Item |

Test Method |

Unit |

Result |

Hardness |

ISO 868 |

Shore D |

78 |

FlexuralStrengthModulus |

ISO 178 |

MPa |

71.22,090 |

Tensile PropertiesTensile StrengthElongation at BreakTensile Modulus |

ISO 527-2 |

MPa%MPa |

65.85.72,490 |

Density |

ISO 1183-1 |

Kg / M³ |

1200 |

Water Absorption |

ISO 62 |

% |

0.08 |

Heat Deflection Temperature |

ISO 75-2 |

ºC |

135 |

Test Report |

2014PC0204 |

||

Sound Insulation (6mm)

Item

Acoustics

Test Method

ISO 140-3:1995

Unit

dB

Result

28

Test Report

2014CB1221

Atmospheric Environmental Exposure (3mm)

Item

Atmospheric test report

Test Method

ASTM G 7-89

Type of Exposure : Direct Weathering

Duration of Exposure : Deterioration basis

Unit

Result

No physical change such as colour change or blistering occurred after 8 years and 10 months of exposure.

Test Report

KD990041

Impact Resistance (3mm)

Item

Impact Resistance

Izod Impact (Notched)

Test Method

ASTM D 256 : 92

Pendulum : 7.5 Joule

Unit

J/m

Result

911 ± 13.8

Test Report

CB990154

Impact Resistance (6mm)

Item

Impact Resistance

Izod Impact (Notched)

Test Method

ASTM D 256

Pendulum : 2 Joule

Unit

J/m

Result

97 ± 3

Test Report

PTS/ER13/330

Impact Resistance (8mm)

Item

Impact Resistance

Izod Impact (Notched)

Test Method

ASTM D 256

Pendulum : 2 Joule

Unit

J/m

Result

116 ± 7

Test Report

PTS/ER13/332

-

The above data fall within the normal range of product specification. The test result obtained with respect to these products are for reference only.

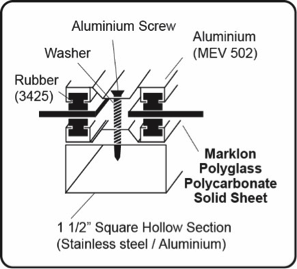

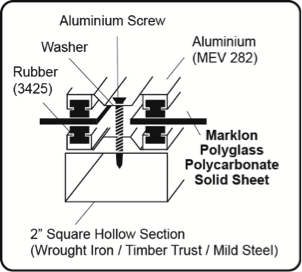

Installation & Storage Method

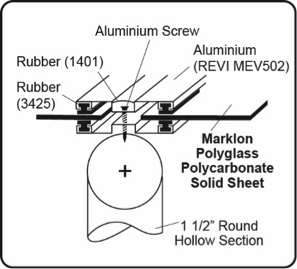

Make sure the support structure is clean and dry. Do not directly screw the sheet, only use aluminium clapping for joining. Must leave a gal of at least 5mm in between sheets for thermal expansion and contraction. A minimum slope of 5º roof pitch is recommended to allow adequate rain water run-off.

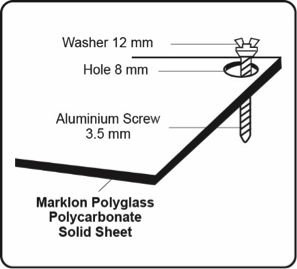

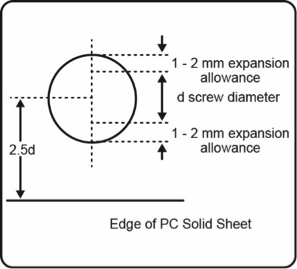

Use only new or sharp ground steel or carbide tipped drills. All holes must be drilled at least 40mm from the edge of the sheet. All holes must be at least 4mm bigger than screw for thermal expansion and contraction.

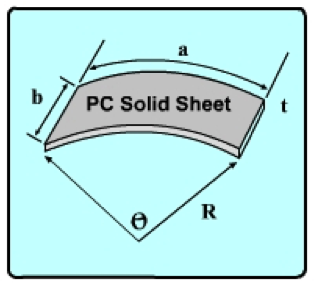

Marklon Polyglass® Polycarbonate Solid Sheet can be cold-form by : –

* a/b >= 2* Ø < 90˚* R >= 180t

Recommended Installation Method

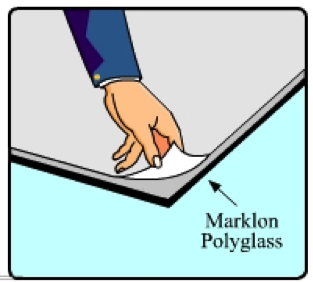

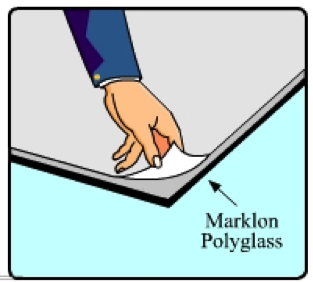

Marklon Polyglass® Polycarbonate Solid Sheet’s is produced with a protective PE film on one or both sides which should be kept on until the panel is fastened. The UV protected side is to be faced towards the sun and is marked with printed film

(Marklon Polyglass®)

To install, 50mm of protective film should be peeled off from the edges of the sheet to allow clean sheet insertion into the glazing system.

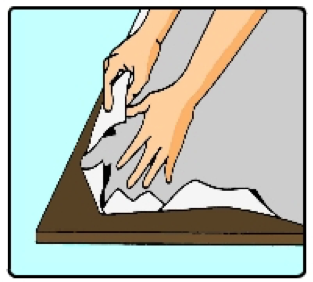

The residual film should be removed immediately after the glazing is completed.

Important Guidelines

For maintenance and storage guidelines

Storage Method

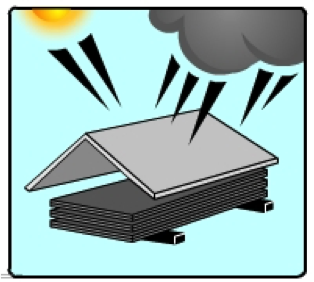

Sheets should be kept indoor, protected from sunlight and rain fall by an appropriate opaque waterproof roof cover.

Cleaning Method

Use only neutral detergent or mild soap for cleaning. Wash by using soft cloth op sponge. Rinse off with lukewarm water (below 60˚C)

Use only neutral silicone for polycarbonate.

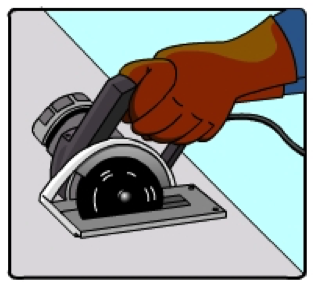

Cutting Method

Use circular saw blade for cutting Marklon Polyglass® Polycarbonate Solid

=============================================================================================================

For more information,

please feel free to contact our customer service chat during working hours.

Working hours: 8.30 am – 5.00 pm

Saturday – Thursday, excluding public holiday & Friday

Whatsapp us now for more information :

012-6964709 or

012-9557709

Download Our Catalogue!

Please fill up your name below to access our catalogue page for download. We promise not to spam you.